Reusing thin stone from urban façades means combining heritage with environmental performance. Thanks to its durability and low carbon footprint, stone becomes a powerful lever for the circular economy. But be warned: the location of the machining process is decisive. Stone reused nearby can be 6 times less polluting than stone reused 1,500 km away!

Tools like ecale.io or the Booster du Réemploi carbon calculator help evaluate impact, but only a precise and contextualized approach guarantees informed choices. In the design phase, an adapted protocol secures projects and paves the way for innovation. The sector is currently structuring itself: architects and engineers, be the pioneers of a controlled, sustainable, and inspiring reuse.

1. Stone Reuse: A Lever to Mitigate Climate Change

Stone is omnipresent on Parisian façades, particularly in the form of thin stone cladding, which has been very common in construction since the 1970s. During renovations or changes of use, the question of the future of these materials arises. Reuse—which consists of dismantling, machining, and reinstalling the stone—stands out as a relevant solution to limit waste and the environmental impact of the building sector. Thanks to its physical and mechanical stability over time, stone is particularly well-suited to this approach.

Approximately 22% of CO₂ emissions linked to stone come from quarry extraction. Reusing material already extracted in the past therefore significantly reduces environmental impact. Furthermore, transport distances to processing centers are often shorter than those to quarries, further decreasing emissions. (1) Thin stone, being lighter than massive stone (approximately 3 cm thick), offers an additional advantage regarding transport, reducing carbon impact proportionally to weight

2. Transport: A Decisive Factor

The RE2020 regulation considers that reused materials have zero impact in terms of Global Warming Potential (3). This assertion is intended to favor and encourage the development of the sector and is taken into account in calculations performed by ecale.io, the parametric façade evaluation tool developed by Arcora.

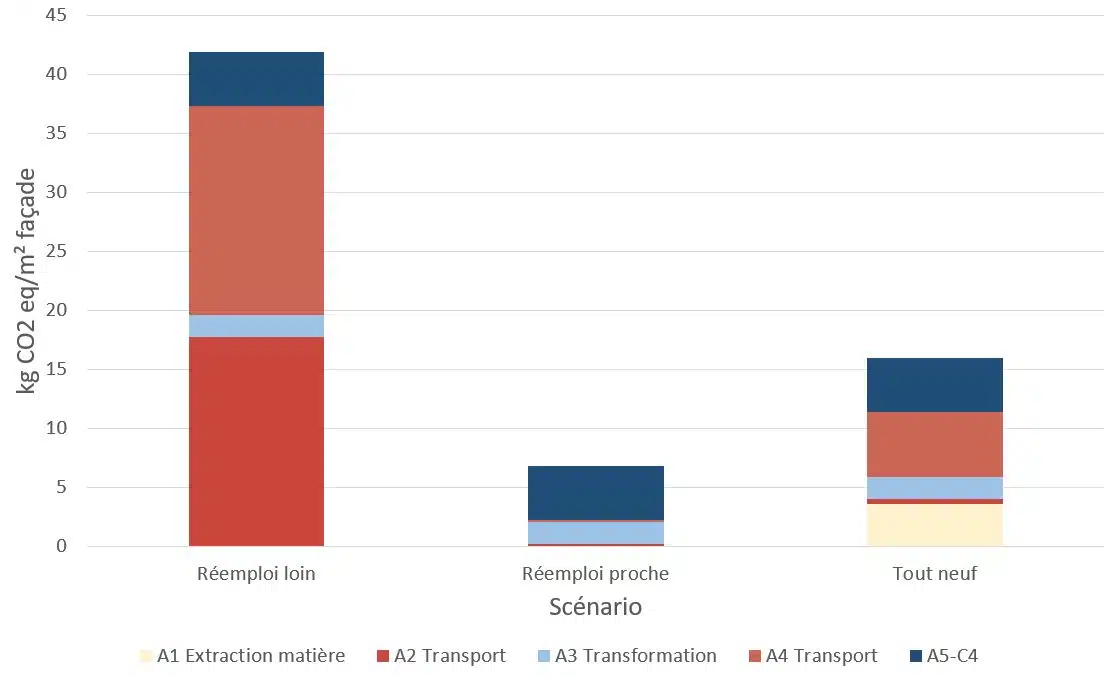

However, a more in-depth analysis reveals that transport can become the main emission source, depending on the distance. The graph above offers an impact analysis of three compared scenarios:

- Distant Reuse: Machining at 1,500 km (e.g., Paris → Portugal)

- Local Reuse: Machining at 16 km

- New Product: Quarry at 466 km

Result: Distant reuse generates a carbon impact 6 times higher than local reuse, and 2 times higher than using new stone. The location of stone transformation and machining workshops is therefore crucial

3. Toward a Unified Method for Impact Assessment

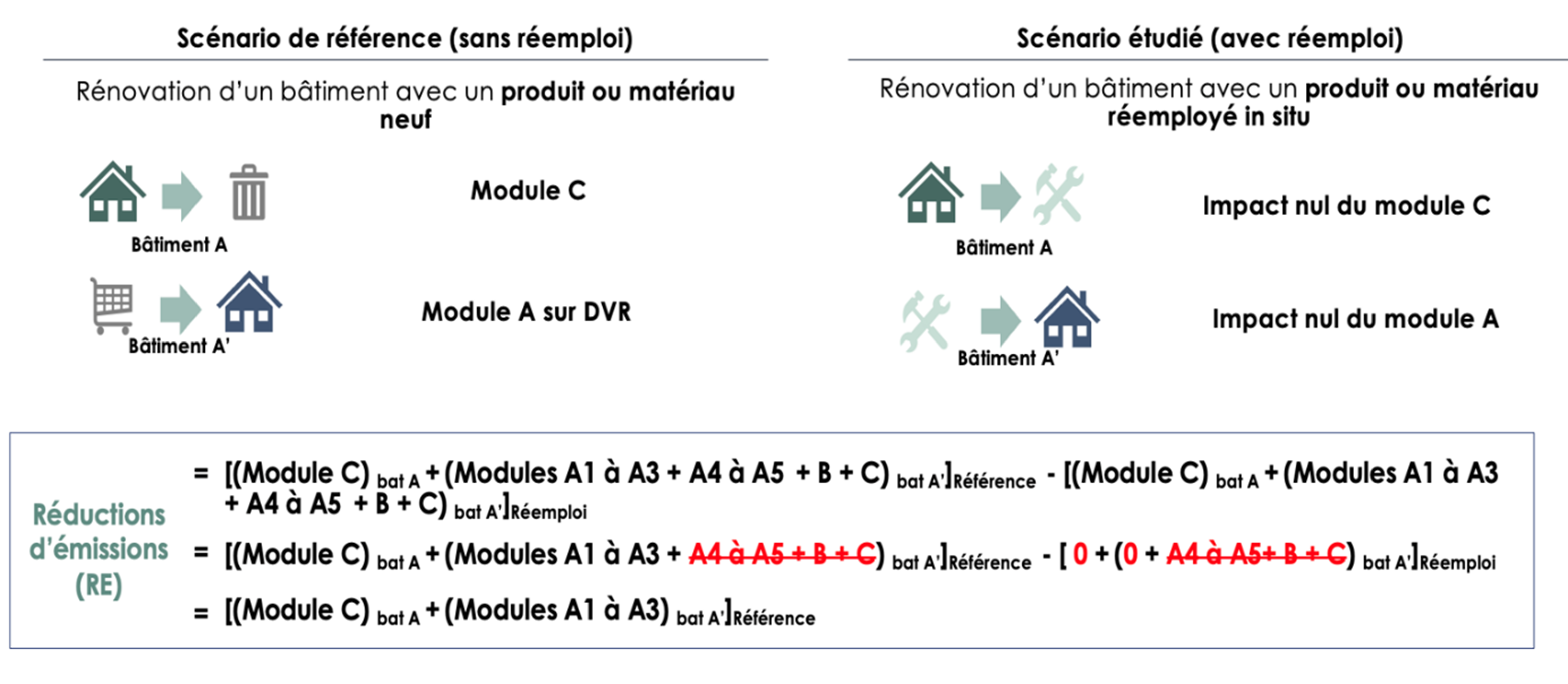

The Booster du Réemploi offers a carbon calculator based on averaged environmental data (4), useful for estimating orders of magnitude of global warming impacts and guiding choices upstream of design. It proposes analyzing avoided emissions according to the calculation method illustrated below:

The Arcora approach consists of analyzing the total cradle-to-grave impact (ImpactR) of the reused product based on environmental data chosen and adapted to transport conditions (Modules A2R and A4R) and the type of reconditioning required (Module A3R). Thus, the impact of reuse is defined as follows :

ImpactR = Module A2R + Module A3R + Module A4R + Modules A5 à C4

The comparison between these two approaches has also highlighted a divergence in how the weight of the reused element, which is directly correlated to transport, is taken into account.

4. Securing Reuse from the Design Phase

In-situ reuse requires a rigorous approach from the design phases. It is essential to identify homogeneous batches of stone slabs and calibrate the number of tests accordingly to avoid additional costs or interpretation errors. A simplified protocol allows for the management of risks related to scheduling, costs, and innovation.

5. A Developing Sector

The reuse of thin stone is an emerging practice in 2025. To date, this reuse remains an innovative technique requiring the development of adapted, precise, and project-relevant protocols. Several projects by Arcora and its peers have already helped overcome certain technical and regulatory barriers, and professional recommendation guides are paving the way (5). Feedback will allow the sector to be structured, similar to the steel sector (6), where professional rules facilitate reuse by reducing insurance and legal risks.

Notes :

- 1) To perform the calculation, the reference used is Combe Brune limestone for the quarry location and density (2320 kg/m³). As the most common thickness of stone slabs is 3 cm, this was taken as the reference for calculating weight per square meter (69.6 kg/m²).

- The FDES INIES sheets used for the calculation are Sheet 35002 and 5555. Sheet 5555 was used to calculate transport impact and thus adapt the exact weight and distances.

- Excerpt from https://www.legifrance.gouv.fr/jorf/id/JORFTEXT000043936431 p.40/1838

- The Booster du Réemploi carbon calculator and its methodological guide can be found on their site: https://boosterdureemploi.immo/ressources/la-calculatrice-carbone-du-booster-du-reemploi/

- For example, the guide “Methodology for diagnosis and performance evaluation for the reuse of attached natural stone façade cladding,” written by the CSTB and the CTNMC. The document is accessible at: [Link]

- The document “Professional Recommendations – Reuse of structural steel elements” paves the way to facilitate reuse. The recommendations are accessible at: [Link]

Illustration photo: Montagne de la Fage project (Arch.: SCAU), delivered in 2024, for which Arcora conducted a support mission on the reuse of stone façade cladding.